Welcome to visit FlowBiz Exports Pvt Ltd

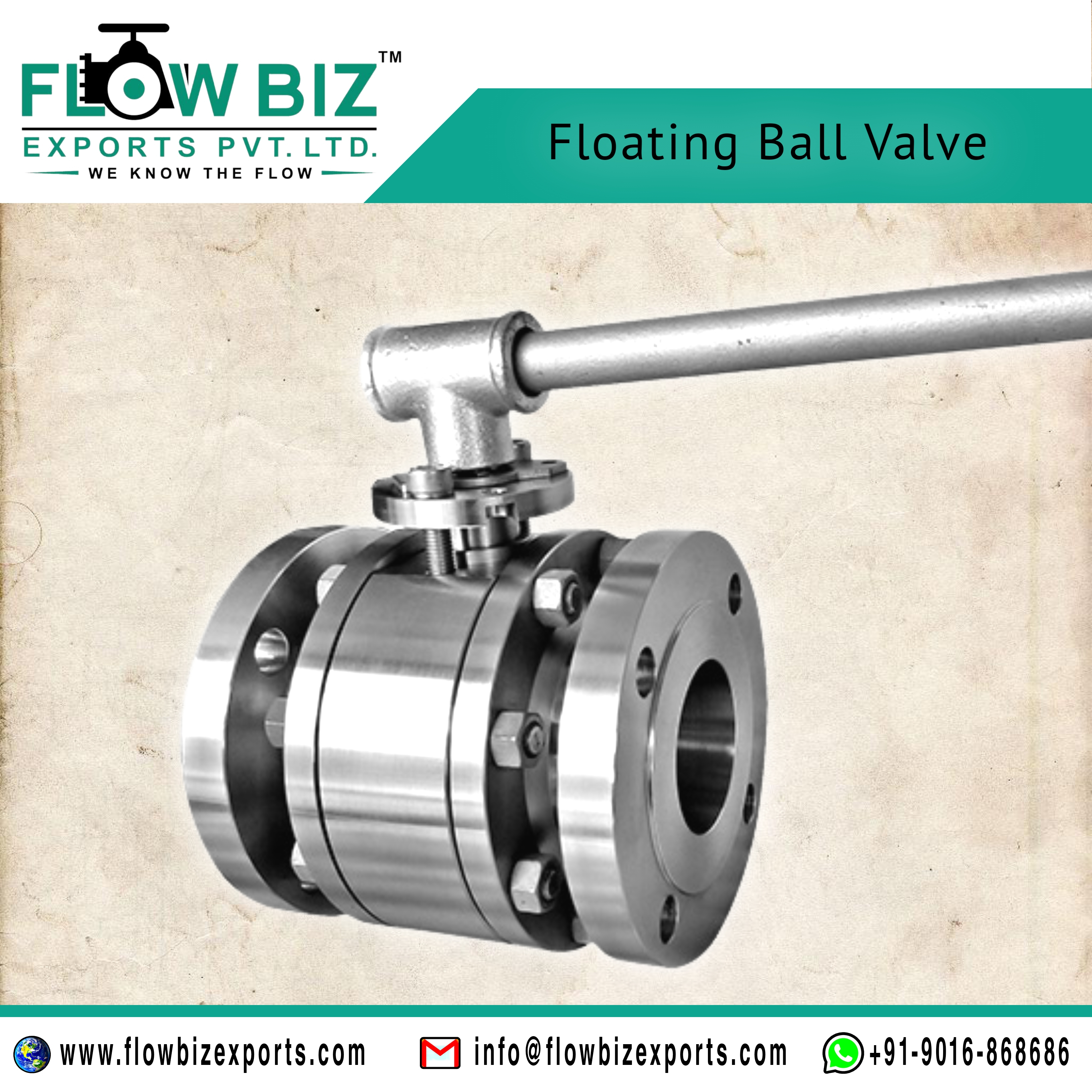

How Do Floating Ball Valves Work?

A pole operates floating ball valves, or stems, connected to the top of the ball that rotates it 90 degrees. As the ball rotates, the port is protected or located by the wall, removing or breaking the media flow. The stem is connected sufficiently to the ball so that, as the ball rotates on its axis, the pressure forces the ball against its downstream center, forming a close seal. For this reason, floating valves may not close as in very low-pressure applications after a certain amount of seat wear because there may be more media force to move the ball against the downstream seat to form a closed seal. However, in most applications, downstream pressure is acceptable to keep a tight seal extended after the centers have started to wear.

Floating Ball Valve Design:

Before we descend into the components of floating ball valve design, let’s define the key elements of a Floating valve:

Valve body – the section in which the valve is covered. Ball valves are generally constructed of steel, iron, brass, bronze, or PVC.

Ball – A pivoting globe with a flow way through the center, connected to the valve body through a stem or rod

Bore or port – the hollow center of the ball

Packing – Relaxed seals that fit around the valve stem to control media from exiting the valve body

Seat – A round, doughnut-shaped disc that creates a stamp between the valve body and ball

Stem – The post that anchors the ball and attaches it to the outer working lever

Actuator – An external machine created to rotate the stem of the valve. A lever, a gear, a motor-operated supply (electric actuator), or a pneumatic/hydraulic actuator.

FlowBiz Exports best manufacturer and supplier of valves and flow control accessories like Gate Valve, Globe Valve, Swing Check Valve, NRV Valves, Ball Valves, Butterfly Valve, Forged Steel Valves, Knife Edge Gate Valves, High-Pressure Ball Valves, Needle Valve, IBR Valve, Plug Valve, Sight Glass, PFA Lined Valves, FEP Lined Valves, Diaphragm Valve, Y Type Strainer, Basket Strainer, Canonical Strainer, to most of the key sectors in India.