The world’s oceans hold some of the most incredible reserves of oil and natural gas. Accessing these key resources takes innovation, ingenuity and a dedication to safety. In 2019 alone, the United States produced an estimated 2.3 million barrels of oil equivalent (BOE) per day. Not only is oil and natural gas used to power our cars and heat our homes, it’s also turned into countless products from clothes and sunglasses to smartphones and laptops to MRI machines and pacemakers.

EXPLORATION

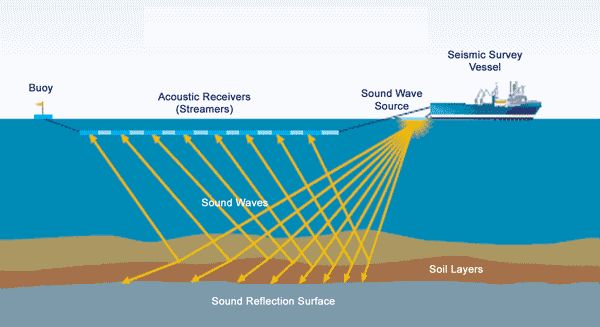

Before offshore oil and natural gas can be extracted, it must be found. Geophysical companies conduct scientific surveys in offshore areas by bouncing soundwaves off the seafloor. In water, the energy source is typically an array of different sized air-chambers, filled with compressed air. The source is towed behind a seismic survey vessel and releases bursts of high pressure energy into the water. The returning sound waves are detected and recorded by hydrophones that are spaced out along a series of cables. Strict mitigation measures are used throughout this process to ensure the health and safety of marine mammals and other marine life.

While geophysical surveys are widely used for oil and natural gas exploration, they are also used for a variety of other purposes including siting for offshore wind farms and locating sand and gravel for coastal restoration.

DRILLING

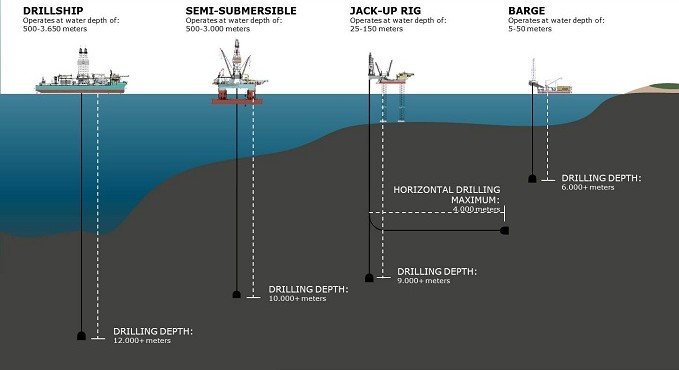

Once a prospective reserve is found, companies will drill highly-regulated exploration wells with Mobile Offshore Drilling Units (MODUs). Some MODUs are converted into production rigs, meaning they switch from drilling for oil to capturing oil once it's found. Most of the time, the oil company will replace the MODU with a more permanent oil production rig to capture oil. There are four main types of MODUs:

- A submersible or barge MODU usually consists of a barge that rests on the sea floor at depths of around 30 to 35 feet (9.1 to 10.7 meters). On the barge's deck are steel posts that extend above the water line. A drilling platform rests on top of the steel posts. These rigs are typically used in areas with calm water.

- A jackup is a rig that sits on top of a floating barge. A ship tows the barge to the drilling site. Once positioned, the jackup can extend legs down to the sea floor. The legs are loaded in such a way that they don't penetrate the floor. Once each leg is secure, the jackup continues to ratchet the legs so that the platform rises above the water level. This keeps the rig safe from tidal motions and waves. Jackups can operate in depths of up to 525 feet (160 meters).

- Drill ships are ships that have a drilling rig on the top deck. The drill operates through a hole in the hull. Drill ships can pilot to the drill site and then use a combination of anchors and propellers to correct for drift as the rig drills for oil. They can operate in deep water conditions.

- Semisubmersibles float on the surface of the ocean on top of huge, submerged pontoons. Some have propulsion systems, which allow them to navigate to drilling sites under their own power while others require a second vessel to tow them to the right location. Most use several anchors -- up to a dozen -- that help maintain the structure's orientation. Computers control the tension on each anchor chain to correct for drift. Some can convert from drilling rigs to production rigs, reducing the need for a second rig to take its place once oil is found.

The MODU's job is to drill down into the ocean's floor to find oil and natural gas reserves. The part of the drill that extends below the deck and through the water is called the riser. The riser allows for drilling fluids to move between the floor and the rig. Engineers lower a drill string -- a series of pipes designed to drill down to the oil deposit -- through the riser.

At the sea floor is the blowout preventer (BOP). The blowout preventer has a pair of hydraulically-powered clamps that can close off the pipe leading up to the rig in the case of a blowout. The BOP is just one of the many overlapping layers of safety precautions the offshore energy takes.

To add stability to the well, the engineers use metal casings, much as they do with land-based oil rigs. These casings help keep the well from collapsing in on itself. Each casing is lined with cement walls. Casings get narrower as the well gets deeper. Oil companies use progressively smaller drill bits as the well's depth increases. At each annulus -- the spot where a narrower casing joins with a wider one -- engineers use a liner hanger O-ring to seal the two sections together.

When the MODU hits oil, engineers must seal the well to prepare it for a production rig. The engineers will use a pair of plugs to seal off the well bore. The bottom plug sits near the oil deposit. Drilling mud or seawater provides the pressure to hold the plug in place while the engineers place a top plug to cap the oil well. Then the well is ready for a production rig to take over.

PRODUCTION

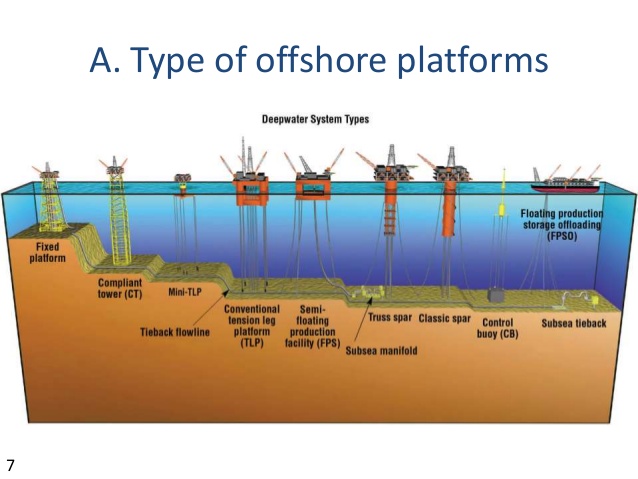

Once a commercial viable well is found, and a company follows the appropriate regulations, operations switch from exploration and drilling to production. The offshore oil and natural gas industry has developed massive engineering marvels that drill at high-temperatures and high-pressures in ultra-deepwater. For every type of offshore environment, there is seemingly a production platform to match.

- Fixed Platform (FP) consists of a jacket (a tall vertical section made of tubular steel members supported by piles driven into the seabed) with a deck placed on top, providing space for crew quarters, a drilling rig, and production facilities. The fixed platform is economically feasible for installation in water depths up to 1,500 feet.

- Compliant Tower (CT) consists of a narrow, flexible tower and a piled foundation that can support a conventional deck for drilling and production operations. Unlike the fixed platform, the compliant tower withstands large lateral forces by sustaining significant lateral deflections, and is usually used in water depths between 1,000 and 2,000 feet.

- Tension Leg Platform (TLP) consists of a floating structure held in place by vertical, tensioned tendons connected to the sea floor by pile-secured templates. Tensioned tendons provide for the use of a TLP in a broad water depth range with limited vertical motion. The larger TLP's have been successfully deployed in water depths approaching 4,000 feet.

- Mini-Tension Leg Platform (Mini-TLP) is a floating mini-tension leg platform of relatively low cost developed for production of smaller deepwater reserves which would be uneconomic to produce using more conventional deepwater production systems. It can also be used as a utility, satellite, or early production platform for larger deepwater discoveries. The world's first Mini-TLP was installed in the Gulf of Mexico in 1998.

- SPAR Platform (SPAR) consists of a large diameter single vertical cylinder supporting a deck. It has a typical fixed platform topside (surface deck with drilling and production equipment), three types of risers (production, drilling, and export), and a hull which is moored using a taut caternary system of six to twenty lines anchored into the seafloor. SPAR's are presently used in water depths up to 3,000 feet, although existing technology can extend its use to water depths as great as 7,500 feet.

- Floating Production System (FPS) consists of a semi-submersible unit which is equipped with drilling and production equipment. It is anchored in place with wire rope and chain, or can be dynamically positioned using rotating thrusters. Production from subsea wells is transported to the surface deck through production risers designed to accommodate platform motion. The FPS can be used in ultra deep water.

- Subsea System (SS) ranges from single subsea wells producing to a nearby platform, FPS, or TLP to multiple wells producing through a manifold and pipeline system to a distant production facility. These systems are presently used in water depths greater than 5,000 feet.

- Floating Production, Storage & Offloading System (FPSO) consists of a large tanker type vessel moored to the seafloor. An FPSO is designed to process and stow production from nearby subsea wells and to periodically offload the stored oil to a smaller shuttle tanker. The shuttle tanker then transports the oil to an onshore facility for further processing. An FPSO may be suited for marginally economic fields located in remote deepwater areas where a pipeline infrastructure does not exist.

Those are just the platforms you can see. Industry has developed subsea production systems that can range from a single subsea well on the ocean floor that connects to a larger platform to multiple wells producing through a manifold and pipeline system to far off facilities. The oil is extracted from the seafloor then tied-back to an existing production platform. One strategically-placed production platform to safely service many wells over a massive area.

Offshore production platforms are modern marvels, but oil and gas cannot make it from below the seafloor to the consumer without human labor. In fact, larger oil rigs often employ more than a hundred workers to keep the platform running. As many of these rigs are located far from cities and shores, the employees (who range from engineers and geologists to divers and doctors) live for weeks at a time on these huge structures.

OFFSHORE PIPELINES

Offshore pipelines are a key part of offshore oil and natural gas production. Pipelines built on the sea floor transport oil and gas from subsea wells to the platform and subsequently gas or oil from the platform to the coast for process and distribution.

Pipelines are classified in three categories:

- Infield Pipelines transport fluids within the field. They are often called flowlines or feeder lines. Infield Pipelines carry a mixture of oil, gas and water from the subsea wells to a manifold or directly from the well to the process platform. A smaller number of infield lines carry processed water from the platform to injection wells for disposal.

- Export Pipelines transport processed oil or gas from the platform to the coast. If the pipeline carries a mixture of oil and gas then it is a multi-phase pipeline. If the pipeline carries only oil or only gas, then it is an sigle-phase pipeline.

- Transmission pipelines carry oil or gas from one coast to another mainly, the same way as a tanker transfers oil for trading purposes.

THE OFFSHORE ECOSYSTEM

Geophysical companies, drillers and producers are just three types of companies that are part of the offshore oil and gas production ecosystem. Thousands of other companies, ranging heavy lift vessel operators, steel fabricators, marine and helicopter transportation, ROV manufacturers, shipbuilders, computer and AI specialists, engineering firms, equipment manufacturers and distributors, welders, pipeline companies, and offshore construction, as well as legal services, lenders and other other professional services are needed to keep America’s offshore energy flowing.

Offshore Oil Production

Offshore Oil Production